Understanding the Core of Dairy Supply: What Every Modern Farm Needs

The Role of Quality Equipment in Dairy Production

In the realm of dairy farming, the quality of equipment plays an instrumental role in determining the overall productivity and profitability of the operation. Unlike traditional farming methods that relied heavily on manual labor, modern dairy operations have embraced technology, leading to increased efficiency and improved animal welfare standards. Quality equipment minimizes the risk of milk contamination, ensures the health of the herd, and ultimately enhances the quality of the milk produced. For instance, advanced milking machines reduce the risk of injury to cows while improving the speed and efficiency of the milking process. Furthermore, high-quality storage tanks maintain the ideal temperature and environment for milk, preventing spoilage and preserving flavor and nutritional value. Investing in robust equipment means investing in the longevity and success of your dairy operation.

Essential Components of a Dairy Setup

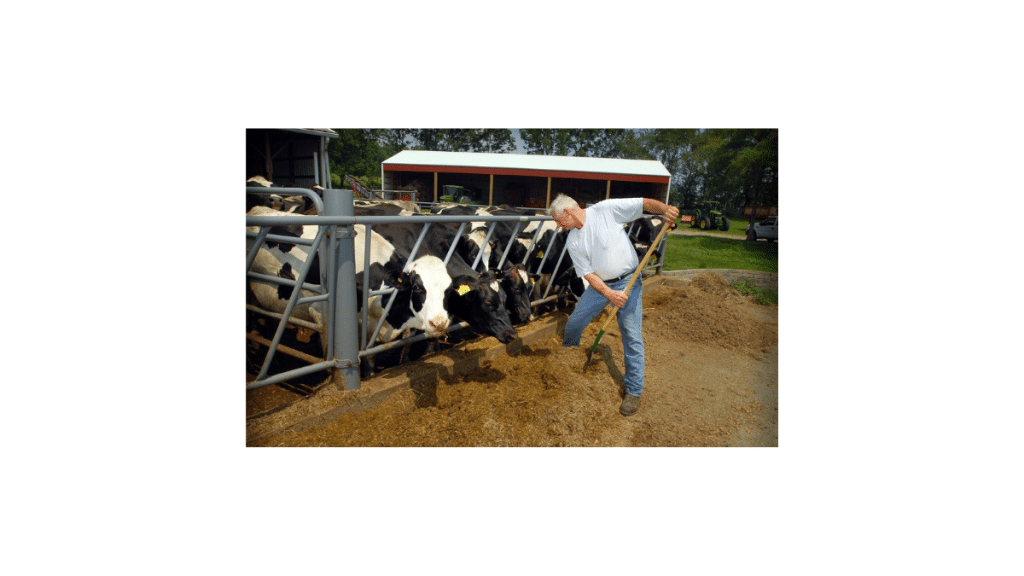

A comprehensive dairy operation requires a multitude of essential components to function seamlessly. Key elements include milking machines, bulk tanks, pipelines, refrigeration systems, and feed management equipment. Milking machines are at the center of the operation, facilitating the milking process, ensuring comfort for the cows, and providing hygienic milk extraction. Bulk tanks are critical for storing large quantities of milk, maintaining low temperatures to ensure freshness until it is transported for processing. Another vital piece of equipment is the refrigerated storage facility, which plays an essential role in preserving the milk quality; however, it is inadequate without a reliable monitoring system to keep track of temperatures and conditions within. Additional equipment such as waterers, feed mixers, and bedding dispensers are essential for maintaining the health and well-being of the herd, indicating that a well-rounded dairy supply is not just about milking but encompasses animal care and welfare as well.

Thinking Beyond the Basics: Innovations in Dairy Equipment

As the dairy industry evolves, so too do the innovations that help farmers increase productivity and manage their operations more effectively. Smart technology is at the forefront of these advancements, revolutionizing traditional farming practices. For example, automated milking systems (AMS) allow farmers to milk their cows without being present, providing greater flexibility and reducing labor costs. Another significant advancement is the use of blockchain technology in dairy supply chains, promoting transparency and traceability from farm to consumer. Data analytics platforms are also gaining traction, enabling farmers to monitor herd health, milk production, and feed efficiency closely. The integration of sensors and machine learning can anticipate equipment failures, thus reducing downtime and ensuring continuous operation. As the dairy landscape becomes increasingly competitive, these innovations are vital for farmers looking to enhance efficiency and bolster their market position.

From Milking to Monitoring: The Equipment You Can’t Farm Without

Milking Machines: Choosing the Right Fit for Your Herd

Milking machines are perhaps the most crucial part of any dairy farm setup. When selecting the right machine, several factors must be considered, including the size of the herd, the milking schedule, and the specific needs of the animals. The primary forms of milking machines include portable, stationary, and pipeline systems. For smaller farms, portable milking machines offer flexibility and ease of use, while larger operations benefit from stationary or pipeline systems that streamline the process. Additionally, modern milking machines come equipped with features such as pulsation control, which ensures a gentle extraction process, and automatic cluster removers that enhance cow comfort by minimizing the duration of the milking process and reducing the risk of mastitis. Understanding the unique needs of your herd and matching those needs with the right equipment is key to maximizing production and ensuring quality milk delivery.

Storage Solutions: Keeping Your Dairy Fresh and Safe

Once milk is collected, it must be stored correctly to maintain its quality. This process begins with bulk tanks, which serve as the primary storage units on dairy farms before the milk is transported to processing facilities. These tanks must be constructed of high-grade stainless steel to prevent rusting and contamination, while also being insulated and equipped with reliable refrigeration systems. Proper aeration must be ensured to combat bacteria growth, necessitating the use of automatic temperature-control systems. Additionally, farmers should consider investing in backup generators or systems that provide redundancy in case of power outages, which are critical in preventing spoilage during unforeseen circumstances. Furthermore, advanced data monitoring systems can track the freshness and quality indicators of milk in real time, alerting farmers to any temperature fluctuations or anomalies that may arise.

Sensors and Technology: The Future of Dairy Management

The integration of sensors and technology in dairy farming heralds a new era of efficiency in herd management. Wearable technology for cows, such as activity monitors and pedometers, can provide real-time data on cow behavior, health, and lactation status, assisting farmers in making informed decisions regarding feeding, breeding, and overall herd management. Moreover, smart feeding systems can optimize feed delivery, ensuring each cow receives the precise nutrition according to her needs, which directly affects milk production. Implementing this technology translates to substantial economic advantages as it maximizes output and minimizes resource waste. Additionally, software platforms that integrate with these technologies allow for seamless data aggregation and analysis, providing insights that can inform long-term cultivation strategies focused on sustainability and profitability.

Efficiency Meets Sustainability: Eco-Friendly Dairy Practices

Energy-Efficient Equipment: Maximizing Output with Less Input

In today’s world, sustainability is not just a buzzword; it’s a requirement for modern dairy operations. Energy-efficient equipment is a pivotal component of this movement. Many dairy farms are now turning to energy-efficient milking machines, refrigeration systems, and lighting solutions, which dramatically lower electricity costs and the carbon footprint of operations. For instance, using variable speed drives on milking pumps can lead to significant energy savings without sacrificing milking speed. Furthermore, farm-wide energy audits can identify areas for enhancement, enabling farmers to implement strategies that reduce energy consumption. Transitioning towards renewable energy sources, such as solar or wind, can also prove beneficial both economically and environmentally, providing a sustainable method for power generation that will be increasingly important in the coming years.

Sustainable Milk Production: How Equipment Plays a Role

Sustainable milk production is multifaceted, encompassing not only environmental considerations but also social and economic factors. Choosing the right equipment plays a vital role in achieving sustainability goals. For example, precision farming technologies that monitor soil health and crop yields can lead to better forage management, which directly impacts the quality of feed, cow health, and milk quality. Moreover, the utilization of anaerobic digesters converts cow waste into renewable energy, addressing environmental concerns while simultaneously providing farmers with a new revenue stream. Dairy farms adopting these sustainable practices often enjoy enhanced public perception and consumer trust, particularly as modern consumers become more conscious of the sources of their food. Thus, investing in sustainable equipment not only aligns with ethical values but positions a farm competitively in the market.

Waste Management Solutions: Turning Challenges into Opportunities

Effective waste management is a critical component of any dairy operation, as it directly impacts profitability and compliance with environmental regulations. Traditional methods of waste disposal are increasingly recognized as inadequate and damaging to the environment; thus, many dairy farms are looking to innovative waste management solutions. Implementing a waste-to-energy system can transform manure into biogas, which can then be converted to electricity or heat; this not only mitigates waste but also creates a functional energy source for the farm. Additionally, composting organic waste offers an eco-friendly way to recycle nutrients back into the soil, enhancing soil fertility and reducing dependency on synthetic fertilizers. These proactive strategies not only help in managing waste effectively but can lead to improved operational performance and enhanced environmental stewardship, crucial in the face of growing scrutiny from consumers and regulators alike.

Investing Wisely: The Economics of Dairy Equipment Supply

Cost vs. Value: Making Smart Choices for Your Dairy Farm

In the agricultural sector, understanding the balance between cost and value is crucial for long-term success. When evaluating dairy equipment supply options, farmers must look beyond the initial price and consider the long-term benefits. While high-quality dairy equipment may come with a higher upfront cost, it often delivers greater value through reduced maintenance, longer lifespan, and improved productivity. For instance, investing in automatic milking systems may require a significant initial investment but can substantially lower labor costs and enhance cow welfare, ultimately leading to higher milk yields. Additionally, energy-efficient equipment can result in long-term savings on utility bills, helping to offset the initial expense. By conducting a comprehensive cost-benefit analysis—factoring in maintenance, production efficiency, and animal health—farmers can make well-informed decisions that strengthen their financial sustainability over time.

Financing Options: Balancing Budget and Quality

Understanding the landscape of financing options available for dairy equipment is crucial for farmers looking to invest wisely. Various institutions offer financing tailored to agricultural needs, including loans, grants, and leasing options. Government programs may provide enhanced benefits for adopting sustainable practices or equipment that increases energy efficiency. Additionally, manufacturers themselves may offer financing options, making it easier for farmers to acquire state-of-the-art technology without significant upfront costs. It’s also advisable to engage with financial advisors familiar with the agricultural sector, ensuring farmers can navigate the options available to strike a balance between budget constraints and quality requirements successfully. By exploring different financing avenues, dairy producers can upgrade their equipment without compromising their operational viability.

Long-Term Maintenance: Protecting Your Investment

Long-term maintenance is a critical consideration when investing in dairy equipment, often overlooked until problems arise. A well-structured maintenance plan not only safeguards your investment but also extends the longevity of essential machinery. Regular inspections, timely preventive maintenance, and adherence to manufacturer guidelines for maintenance can significantly mitigate breakdowns and operational downtime. Additionally, maintaining accurate records of maintenance activities not only assists in tracking the performance of the equipment but can also bolster warranties and inform decisions regarding future upgrades. Investing in maintenance training for staff can enhance the operational capability of dairy farms and ensure equipment is utilized to its fullest potential. Ultimately, a proactive approach to maintenance safeguards the efficiency and effectiveness of the dairy operation.